Consulting and development

We enthusiastically tackle complicated customer requirements when it comes to the production of plastic profiles. The requirements are very diverse and demanding. This is what motivates us to constantly develop and do our best to find tailor-made product solutions for every customer and to reliably implement and manufacture them.

We develop your products based on samples, sketches or drawings. Our own development team combined with our in-house toolmaking department makes this possible.

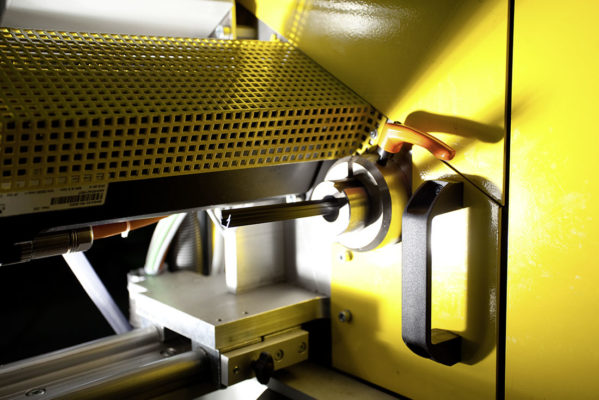

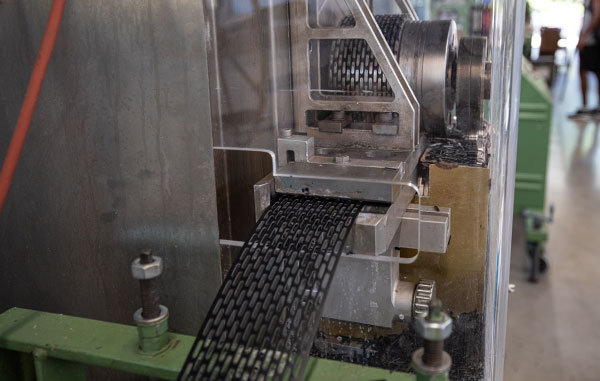

Production

Different plastics (including PVC-U, PVC-P, PP, ABS, HD-PE, LD-PE, PA, TPU, TPV, TPS, EVA) are processed into high-quality products on over 20 extrusion lines in Herborn.

With a great deal of experience and technical expertise, we are also happy to meet your product requirements in the specialised field of plastic profiles.

Quality and certification

The precision and quality of the products in the

“Manufacture of plastic products by extrusion process and toolmaking”

field has been certified by DEKRA ITS Certification Services within the framework of DIN 9001:2015

and is subject to an annual monitoring audit.

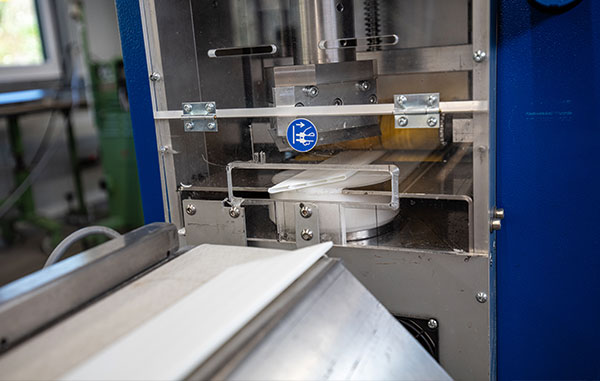

Assembly

Besides the common extrusion types and the combination of two hardnesses in one profile, we also offer the processing of special materials with the following properties:

- UV-protected

- Treated with fungicide

- Sliding coating

- UL 94 V-0 listed

- antistatically equipped

Our profiles can be delivered to you either as fixed lengths or as rolls. We also fulfil a wide range of assembly requirements:

- Stamps

- Drilling

- Imprints

- Adhesive and velcro tapes

- Stretch protection

- Profiles welded to rings or frames

- Milling cuts

- Brush feeding

Deutsch

Deutsch